Tel. +420 281 012 572

Fax +420 281 012 575

E-Mail: info@hahnautomation.com

Digital Advanced Automation at Automatica!

On June 22nd, 2021 at 1 p.m. (CEST) we will present you the most modern systems for optimizing your production with intelligent and digital automation technologies in our company session. Register with our visitor code HAHNsprint21 and experience Digital Advanced Automation: How to optimize your production with intelligent and digital automation technology worldwide.

Learn more about Digital Advanced Automation

In the HAHN Group Company Session „Digital Advanced Automation“ for Automatica 2021, we will show you how you can further optimize your production with the use of intelligent and digital automation technologies. You can look forward to an insight into the structures of the HAHN Group as well as a case study from the healthcare industry. Using this example, we will show you what advantages the combination of competencies within our group has for our customers and partners.

Products & Services at a glance

In addition to the detailed case study as a video presentation, you can also find out more about selected products and services from our company network here and in the HAHN Group company profile on the Automatica website.

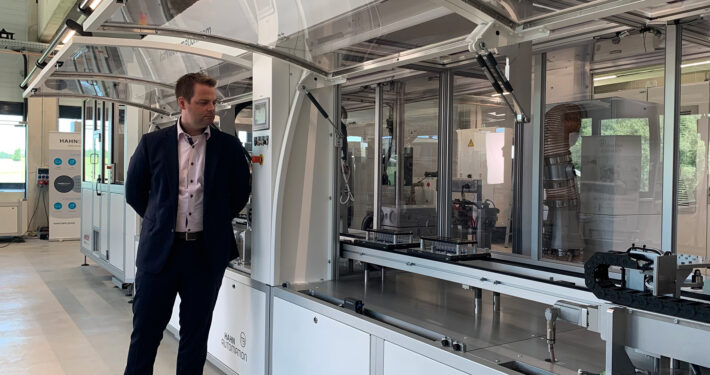

Battery Test Stand - HAHN Automation

Global developments and innovations increasingly demand standardized and intelligent manufacturing solutions. HAHN Automation has developed integrated, comprehensive solutions, from assembly and processes to complex test engineering. The concepts of the test systems are always adapted to the needs of the operators. For this purpose HAHN Automation continuously develops its own test processes and can continuously improve and optimize them.

HAHN Automation’s test engineering is not only adapted to the latest state of technology, but also designed to be particularly efficient. The test processes are real time capable and based on PC-supported systems. The user interface of the test application is fully integrated into the plant control system and adapted to the needs of the production. In addition, it is possible to access and manage all information relevant for the test engineer in special menus. Integration of test systems and interfaces of all common bus systems for the control of actuators in the automobile are a matter of course for HAHN Automation.

Dyna Check Shock Absorber - HAHN Automation

DynaCheck Shock Absorbers specialize in the functional testing of closed and fully assembled single and twin-tube shock absorbers. The test can be carried out with previously defined parameters and variably configurable measurement tasks. With two integrated linear drives, all motion profiles can be run, which enables testing with different strokes and speeds. The user interface of the test system is fully integrated into the system control and adapted to the production requirements. A central panel is used to control the entire system and enables the test engineer to clearly display relevant information and measurement results.

EOLT Turbo Charger - HAHN Automation

HAHN Automation has developed a cold gas test bench for exhaust gas turbochargers, which can be fully integrated into the production line of these. In this cold gas test, the internal combustion engine is simulated in order to evaluate the quality of the respective turbocharger on the basis of critical characteristics. The entire test is fully automatic and line-integrated.

SmartSolutions - HAHN Automation

The new SmartSolutions product portfolio offers manufacturing companies a new way to efficiently automate starting with a minimum quantity of one piece. The industrial processing systems from HAHN Automation map a multitude of processes and can be operated by everyone. Thanks to the software innovation SIA (smart intuitive automation), operators can set up and control the system on the tablet using symbols and graphics. The intuitive design of the SIA user interface is already known to many from the smartphone, which keeps the entry barrier low.

EVE Suite - HAHN Digital

With EVE Suite, HAHN Digital provides a portfolio of innovative solutions that put the digital transformation of tomorrow’s Smart Factory into practice. Upon the integration of EVE Suite services into their processes, users can noticeably increase their output regarding the most important factors: Productivity, Efficiency, Quality, Flexibility.

Mobile Robots - HAHN Robotics

HAHN Robotics, as a successful integrator of driverless transport systems for many years, increases the efficiency of processes in companies. Employees are freed from intralogistic activities and can be assigned to other tasks, thus enabling higher operational effectiveness and sustainable productivity increases. The freely navigating AGVs allow a quick and easy commissioning without changing the existing infrastructure and workstation arrangements. The flexible use of Mobile Robots replaces permanently installed conveyor technology and supports the internal material flow for optimized production processes.

Palletizing Kit - HAHN Robotics

The Palletizing Kit is an easy-to-use, ready-to-use and fully integrated palletizing solution that, when combined with a Cobot, allows you to automate unpleasant, stressful and time-consuming tasks unencumbered and without significant adjustments to your production layout.

A centrally positioned control cabinet unit and an optional telescopic lifting column that carries the robot are stationed on a mobile frame equipped with castors. The palletizer, which is thus extremely compact, requires comparatively little space and can be used flexibly in your company wherever it is needed.

Particularly interesting: In addition to the automation components, the Palletizing Kit can be individually expanded with further peripherals and accessories from our portfolio – e.g. with a vision system for position and location detection. An intralogistic connection of the pallet locations to product feeding conveyors or to a driverless transport system is also possible.

Certification as a Universal Robots+ Application Kit identifies the palletizing solution from Dahl Automation and HAHN Robotics as a „Plug & Produce“ automation system especially suitable for Cobot use. For loads over 10 kg, further versions with larger robots such as the brand new Yaskawa HC20 are in preparation.

VARIO TIP® - Waldorf Technik

The VARIO TIP® system from Waldorf Technik is the patented and worldwide leading system concept, for example in the production of pipette tips. These products are laboratory consumables that must fulfil high quality requirements and they demand cavity sorting in the packaging unit to guarantee delivery reliability and patient safety in every case. With the VARIO TIP® system production runs completely cavity sorted for maximum efficiency and safety.

VARIO TIP® stands out with peak values in manufacturing with cycle times of 3.8 seconds and high cavity numbers up to 128. The VARIO TIP® system is characterized by its unsurpassed level of freedom for different tool configurations and packaging units. The automation system takes on all basic functions such as take-out, transfer, change pattern, buffering and filling. In addition, the system includes a large number of unique functionalities depending on customer specific needs. This includes camera inspections, cavity-sorted replacement of bad parts, filter assembly and customized packaging of the finished parts.

The VARIO TIP® FSS system with its slimline design opens up the market to MedTec injection moulders in new performance classes, without the need for more cleanroom space. FSS means “Floor Space Saving” – the outstanding advantage of the VARIO TIP® FSS over the standard VARIO TIP® model lies in the extremely reduced surface requirements. Through skilful arrangement of the buffer surfaces needed to separate the cavities, Waldorf Technik has succeeded in once more halving the area required by the basic system. Naturally enough, tool and product quality are maintained, as are functionality and variability.

xPacker - WEMO

WEMO xPacker is a completely new concept for the handling and packing of boxes on pallets, providing an industrial logistics solution for material handling. The system consists of a robot, incoming conveyor and integrated safety guarding, making it ready for easy “plug-in” directly after the out coming conveyor belt from the moulding machine or within a centralized logistics department. All types of boxes or packages can be handled with a unique vacuum gripper, which can detect the size and selectively use the necessary vacuum channels. Due to the easy and intuitive programming through the WIPS handling software, less knowledge is required to operate this unit in an efficient way.

WSV spray valve - Walther Systemtechnik

The electric universal spray valve for reliable and consistent application of low to medium viscosity media combines smart technology in the smallest space. With integrated electronics for control, monitoring and evaluation, Ethernet-based bus system, four DIOs for connecting peripheral devices, temperature control and pressure sensor for analyzing the process pressure curve, the spray valve offers maximum flexibility, user-friendliness and process reliability in application. It is suitable for both intermittent and continuous application of different media (e.g. oils, release agents, paints, greases, etc.). Since no additional control technology, software or programming is required for integration, this is done in a cost- and time-saving manner. Direct access via web interface also enables quick and easy commissioning as well as flexible parameterization using a computer, tablet or smartphone. Additional features such as the control of the atomizing air via a proportional pressure valve (the control system otherwise required for this is omitted), the built-in pushbutton for manual actuation and the subsequent expandability via upgrade round off the extensive performance features of this new valve type. Due to its very compact dimensions, it can be integrated not only into new plants and systems, but just as easily into existing ones.

Highlights

- Integrated web server for browser-based parameterization

- Selectable parameter sets for independent control of opening and closing times, atomizer air pressure, and pre- and post-air duration

- Continuous process monitoring in real time

- Freely configurable alarms/messages based on different process variables and operators (optional)

- Integrated valve heating and temperature control (optional)

- Pressure sensor monitoring and evaluation of the process pressure curve (optional)

- DIO’s for conventional valve control and connection of peripheral devices

- Integrated push button for manual operation

- Optical status display on the valve body (LED)

- Different nozzle and air cap combinations for a perfect adaptation to the desired spray pattern

- for complex spraying tasks, we offer a variety of adapted nozzle extensions optionally

Benefits

- Valve for automated application of viscous media

- Fast and easy commissioning and direct control via web interface

- Cost- / time-saving integration without additional control technology, software or programming

- Analysis and optimization of the process through display and recording of process variables

- Reduction of rejects and increase of process quality by continuous process monitoring

- Individual performance expansion through subsequent upgrades

- High flexibility through automated or manual operation

- Repeat-accurate assembly through integrated centering hollows

- Compact design allows integration into existing production lines

DISCOVER THE HAHN GROUP – VIRTUALLY & LIVE ON SITE

Immerse yourself in the VR world and experience the business areas of the HAHN Group in the new VIRTUAL.EXPO. Take the opportunity to find out more about the technologies, products and solutions of the HAHN Group companies ahead of the next trade fairs.

We are also happy to offer you an interactive tour of the virtual showroom. Our experts will give you personal information on our current topics during a telephone call. Just ask for your personal appointment by email!

Impressions of the VIRTUAL.EXPO

Mit dem Einsatz von Cobots, AMR und AGV revolutioniert HAHN Robotics die Welt der Intralogistik. Erfahren Sie hier, was hinter diesen Technologien steckt und welches Potenzial diese für die moderne Produktion bergen.

Mit Hilfe von Roboter- und Automationstechnik in der Industrie können die Produktionszahlen für medizinische Produkte bei Bedarf schnell hochgefahren werden. Die HAHN Group ist mit ihren Unternehmen ein starker Partner für die Healthcare-Industrie.

Mit SmartSolutions bietet HAHN Automation eine Lösung zur industriellen Automatisierung ab Stückzahl Eins vor. Diese Systeme können eine Vielzahl von Bearbeitungsprozessen abbilden, bei gleichzeitig besonders einfacher Bedienung.

Mit digitalen Technologien wie Virtual Commissioning oder dem EVE Suite Portfolio treibt die HAHN Group die Digitalisierung von produzierenden Unternehmen voran.

The speakers

Philipp Unterhalt

HAHN Robotics

Uziel Zontag

HAHN Robotics

Martin Schmitz

HAHN Robotics

Henning Wagner

HAHN Robotics

Philipp Klaschka

HAHN Robotics